ــــــــ products ـــــــــ

Mempack

———

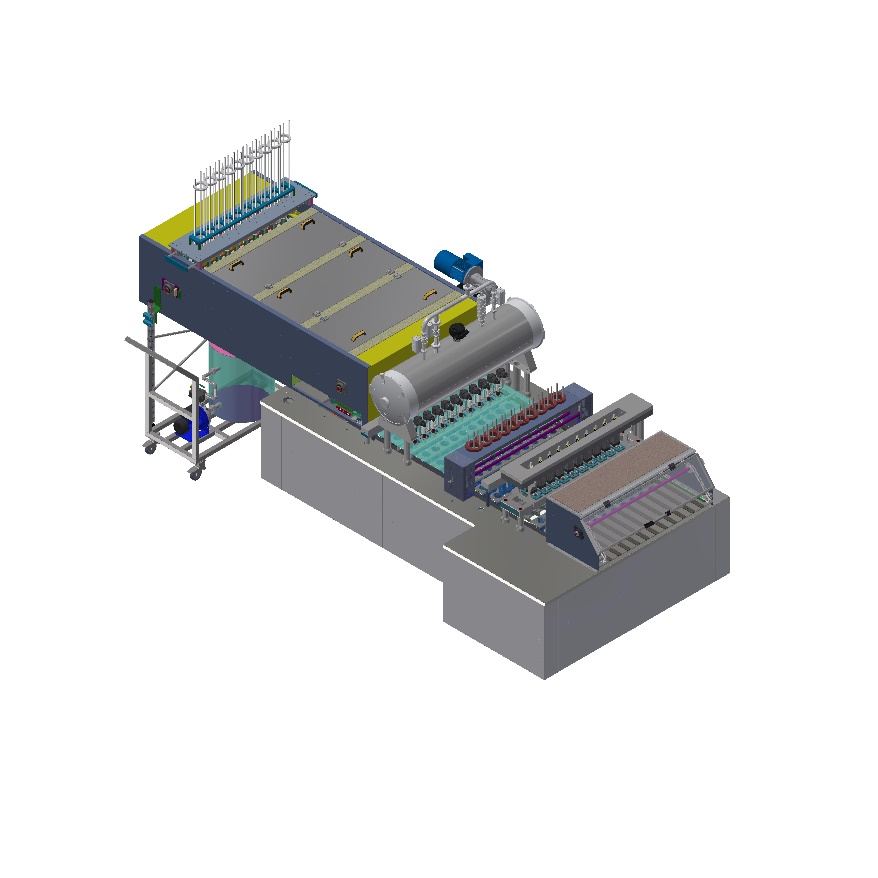

Cups automatic filling machine

This machine has been manufactured to satisfy important productions (up to 12000 pieces per hour) depending on the filled product. And to be easily modified in its con figuration: it is very simple to add optional stations, if necessary.

The standard model is suitable for seal and cap, water, juice products container. This machine can work pre- formed containers.

The standard model can use pre-cut lids made of aluminium, which has to be compatible with the containers.

APPLICATION FIELDS:

DESIGN

The 1210 model is an in-line filling sealing machine, completely automatic, able to Package 10-container per cycle. The machine is totally made of stainless steel and Aluminium treated, so that it can be used in damp environments.

The cleaning and maintenance operations are very simple.

All the principal movements are pneumatically, and its working is controlled by a Microprocessor Control. The machine is endowed with a stainless-steel base and it is driven by a motor moving 2 big side chains, to which are fixed the container-carriers to convey the containers during production.

The machine is equipped with the following working stations:

1) Placing station; it handles the container from the in-feed magazine into the container Holders which located on the moving plates.

2) De-nesting device for embossed alu-lids, working by vacuum and composed of a shaft with 10 sucker holders which are mechanically driven, 10 lids dispensers and a detecting System for lids.

3) 10 filling heads and dosing device it can be regulated from 100 cc. To 300 cc each.

4) Thermo sealing head, equipped with 10 sealing heads manufactured according to the Customer’s container, pneumatically driven, electronically timed and individually thermo regulated.

5) Ejection Station composed of:

– 2 mechanical lifting devices which take the containers from their seat and lift them to the same level as the ejection conveyor;

– A mechanical arm which transfers the containers to the collecting conveyor; a motorized ejection conveyor (about 3000 mm long) which can be supplied with collecting conveyor.

The control panel is simple to use. It has got a keypad with display screen and allows for control

of all the machine functions.

Weight Kg.: 1500 roughly

Power requirement: 220/380 VAC 3 ph + N+ PE 60 HZ

Compressed air supply requirement: 700 Lt/ minute – 7 bars

Output: up to 12000 CPH (depending on the cup size)