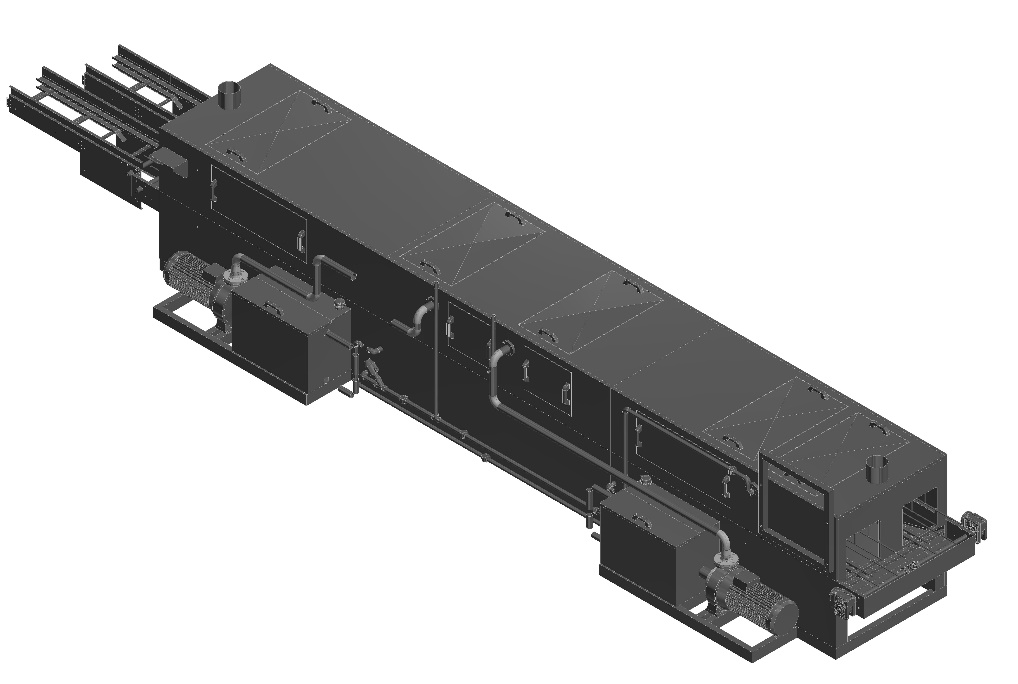

Automatic Washing system

The washing system contains:

- Water Consumption of 1 L/min:

The pallet washing system is designed to minimize water consumption, utilizing only 1 liter per minute. This efficient water usage helps reduce costs and conserve water resources while maintaining effective cleaning results. The system ensures optimal cleaning performance with minimal environmental impact. - Stainless Steel Square Tube Structure:

The structure of the washing system is built using a stainless steel square tube, specifically a 40x40mm welded structure. Stainless steel is chosen for its corrosion resistance and durability, making it ideal for industrial applications. The seams of the structure are treated with acid and brushed to ensure a smooth and clean surface. Additionally, the standard surface treatment is a marble brush finish, providing an aesthetically pleasing appearance. - Stainless Steel 316 Tanks with Manhole:

The tanks within the washing system are constructed using stainless steel 316, a high-quality and corrosion-resistant stainless steel grade. The inclusion of a manhole allows for easy access and maintenance of the tanks. The stainless steel construction ensures the longevity and reliability of the tanks, even in demanding industrial environments. - Spraying System with 35 Nozzles:

The washing machine is equipped with a spraying system consisting of approximately 35 nozzles. These nozzles are strategically arranged to spray water on all sides of the pallet, ensuring comprehensive cleaning coverage. The spraying system is designed to deliver optimal water pressure and flow to effectively remove dirt and debris from the pallet’s surfaces. - Effective Dirt Removal:

The pressure and special configuration of the nozzles are specifically arranged to knock down and remove all dirt from the pallet. This design ensures thorough cleaning, leaving no residue or contaminants behind. The washing system’s precise nozzle arrangement and controlled water pressure contribute to efficient and effective dirt removal

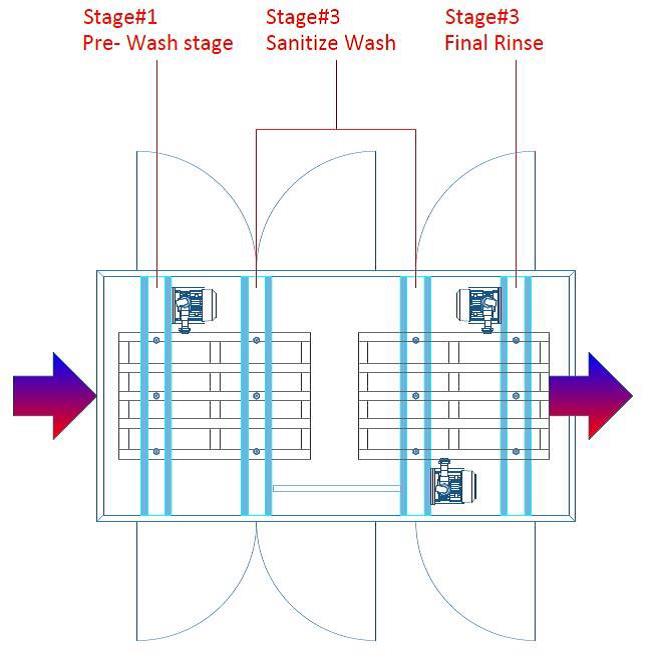

Stages of washing:

a. Pre- Wash stage:

Where dirt of pallet is removed by plain water.

This section has pump located underneath that constantly recirculates the water through the jets and back into the tank.

The tank has 4 bolts easy access manway located on the side.

b. Mid-wash (optional: Sanitize Wash)

Where water used is warm and mixed with detergent.

Wash solution should be added to the wash tank via the wash section area.

c. Final Rinse:

Water used in this stage is same product water or meet the same local codes to remove any sanitizer solution that may be left from the sanitize section.

Applicable for plastic pallets / plastic crates / different types of containers